Milk Tester

Milk Analyzer

Milk Tester Manufacturer

Ensure Nutrition in Every Drop of Milk

Get A QuotePortable Design for Easy Milk Testing

Instant On-Site Testing with Rapid Result

Introduction to Milk Tester

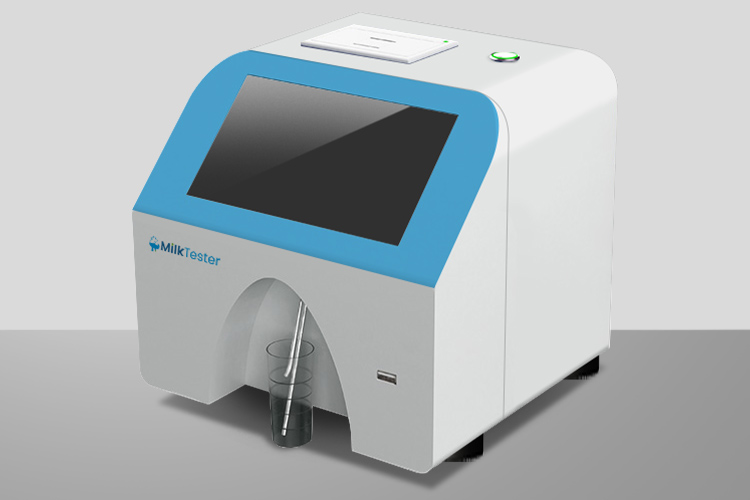

Milk tester, also called milk analyzer, is a high-precision detection device specially designed for dairy farmers, dairy processing plants and research institutions. It is mainly used to quickly measure key indicators such as fat, protein, moisture, lactose and density in liquid milk. As a natural food, milk quality directly affects the taste, safety and nutritional value of dairy products. Therefore, timely and accurate detection of milk source components is of vital importance for ensuring the quality of dairy production, optimizing the management of dairy cow feeding and enhancing consumer trust. The emergence of milk tester has effectively replaced traditional manual testing and chemical analysis methods. It not only enhances testing efficiency but also significantly reduces labor and reagent costs. Also, milk analyzer is easy to operate and can be mastered without a professional technical background, meeting the dual demands of on-site rapid detection and high-precision analysis in the laboratory. Through milk tester machine, users can immediately grasp the quality of the milk source, achieve scientific management and data-driven decision making, ensuring the safety and stability of dairy products from the source to the finished product.

The design concept of milk tester is portability, efficiency and reliability. The compact and lightweight body enables users to operate easily on the dairy farm site and check the quality of the milk source at any time. The feature of quick result generation can help dairy enterprises improve production efficiency and shorten the testing cycle. Besides, milk tester is not only suitable for routine testing of whole milk and skimmed milk, but also can meet the analysis requirements of special milk types such as goat milk and donkey milk, providing diverse solutions for different users. By using milk analyzer machine, dairy farmers and dairy enterprises can scientifically manage milk sources and optimize production processes, enhancing the overall quality and market competitiveness of dairy products.

Experiences

More than 20 years Milk Tester Manufacturing

Certifications

ISO9001 approval company, product comply with international standard

Customization

Rich experience in tailor-made Milk Tester

Delivery

Worldwide delivery and short lead time

Working Principle of Milk Tester

Milk tester typically adopts ultrasonic technology, which is a highly accurate non-destructive testing method. Through ultrasonic sensors, milk analyzer can accurately measure components such as fat and protein in milk samples and even correct the influence of changes in sample temperature and acidity on the test results. The core principle is to use the characteristic changes of ultrasonic waves when they propagate in liquid milk to determine the composition of the milk. The densities and viscosities of substances such as fat, protein and water in milk are different, which will have specific effects on the propagation speed, attenuation and impedance of ultrasonic waves. Milk tester emits high-frequency sound waves into the milk sample through sensors, simultaneously receiving reflected or transmitted signal. Then, it combines the built-in algorithm to calculate the specific values of indicators. This detection method does not require chemical reagents, which is environmentally friendly and safe. At the same time, it can achieve rapid, continuous and multi-parameter synchronous measurement, greatly improving the efficiency and accuracy of on-site and laboratory detection. The physical measurement principle of the ultrasonic milk analyzer not only reduces the consumption of samples but also significantly enhances the detection speed and accuracy, making the detection process efficient and reliable. It is suitable for on-site rapid detection and also provides a scientific and traceable quality control basis for dairy industries.

Why Choose Milk Tester for Milk Quality Analysis?

Ensure the quality&safety of dairy products

Milk tester can instantly grasp the components of the milk source to ensure that indicators of dairy products meet the standards, reducing quality fluctuations and safety hazards.

Quickly detect abnormal milk sources

Through real-time detection,abnormal indicators such as low fat or abnormal protein in milk can be detected in a timely manner, preventing substandard milk from entering the production process.

Optimize management&feeding plans for dairy cows

Dairy farmers can adjust the feed ratio, feeding methods or herd management based on the test results to increase the milk production and the stability of milk quality of dairy cows.

Improve production efficiency and save time

Compared with traditional chemical testing method, milk analyzer can measure on the spot and provide results in just a few seconds, significantly reducing waiting time and improving the efficiency of dairy production.

Save labor and consumable costs

No chemical reagents or complex operations are required. This test can reduce labor and consumable costs while minimizing sample waste. The use of milk tester can significantly save the overall operating costs of milk source management.

Provide traceable test results

The test results can be saved and exported for long-term data analysis and quality tracking, providing a scientific basis for decision-making. Also, it can ensure that every batch of milk meets safety and nutrition standards.

Key Milk Parameters Measured by Milk Tester

Milk tester is a high-precision device specifically designed for detecting the composition and safety indicators of milk. It not only enhances the quality control level of milk production, but also provides data support for the health and safety of consumers.

Fat: Fat is an important nutrient in milk, directly affecting its taste and nutritional value.

Protein: Protein is a key nutrient in milk, influencing its nutritional value and processing characteristics.

Lactose: Lactose is the main carbohydrate in milk and is particularly important for people who are lactose intolerant.

Ash: Ash assesses the mineral content in milk and helps determine the quality and nutritional value of the milk source.

Total non-fat solids: It reflects the sum of all non-water and non-fat substances in milk and affects the overall quality of milk.

Milk density: Milk density is an important parameter for judging the purity, dilution degree of milk. It can also reflect the influence of feed ratio, milking time and storage conditions.

Milk temperature: The sample temperature not only helps to determine the environmental conditions of the milk, but also directly affects the detection accuracy of other components.

pH value: It is used to test the acidity or alkalinity of milk to determine its freshness and quality stability.

Water adulteration rate: This rate is used to test whether the milk has been adulterated with water to ensure its purity and authenticity.

Freezing point: It can test the freezing point of milk to assess its purity and quality and prevent adulteration.

Conductivity: By testing conductivity, the content of electrolytes and minerals in milk is evaluated to determine its freshness and purity.

Core Technologies of Milk Tester

Ultrasonic precision detection technology

Milk Tester adopts an advanced ultrasonic sensing system. By detecting the changes in the propagation speed and density of high-frequency sound waves in milk samples, it accurately calculates the content of key components.

Automatic temperature compensation system

Milk analyzer is equipped with a highly sensitive temperature sensor that monitors the sample temperature in real time and automatically corrects the test results to ensure the stability and accuracy of the data.

Intelligent signal processing algorithm

In combination with the algorithm module, the built-in microprocessor chip of milk tester can reduce noise, amplify and dynamically correct the detection signal, effectively eliminating errors caused by environmental vibration.

Multi-parameter rapid analysis

It only takes a few seconds to simultaneously obtain multiple detection parameters, including fat, protein, density, water dilution ratio, non-fat solids and so on. The system automatically calculates and generates a complete report.

Automatic cleaning function

To ensure detection accuracy and hygiene safety, ultrasonic milk analyzer is equipped with an automatic cleaning system. The device will start the cleaning program to quickly flush the flow channel and the detection module after testing.

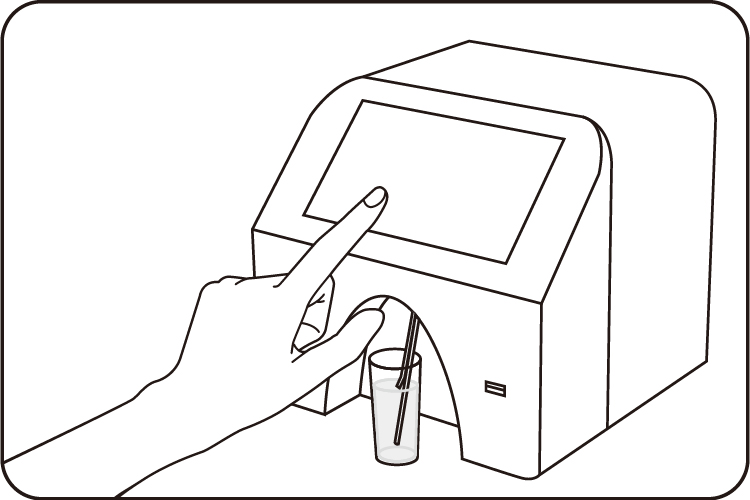

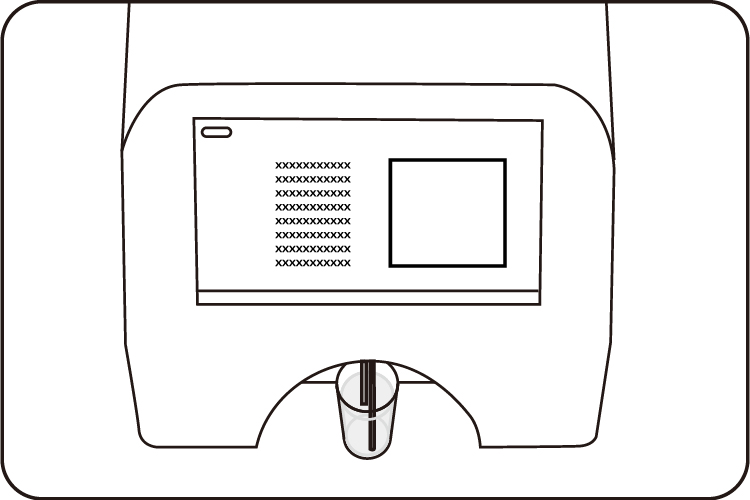

Digital display interface

Milk tester adopts a modular structure and digital display interface, which is easy to operate and maintain. The portable design is suitable for quality control sites in farms, milk stations and dairy enterprises.

Features of Milk Tester

Portable design for on-site testing

Multi-parameter simultaneous testing

Fast response and rapid result reading

High-precision sensor and intelligent algorithm

Automatic temperature compensation

Automatic cleaning system

User-friendly digital display interface

Suitable for diverse environments

Data management functionality

Compatible with multiple milk sources

Application Scenarios of Milk Tester

Dairy Farm

Dairy Processing Facility

Milk Collection Center

Milk Retail and Distribution

Milk Transportation

Milk Research Institution

Applicable Milk Sources for Milk Tester

Cow Milk

Goat Milk

Sheep Milk

Donkey Milk

Buffalo Milk

Camel Milk

Reconstituted Milk

UHT Milk

How to Operate Milk Tester?

Prepare milk sample and make sure they are thoroughly mixed

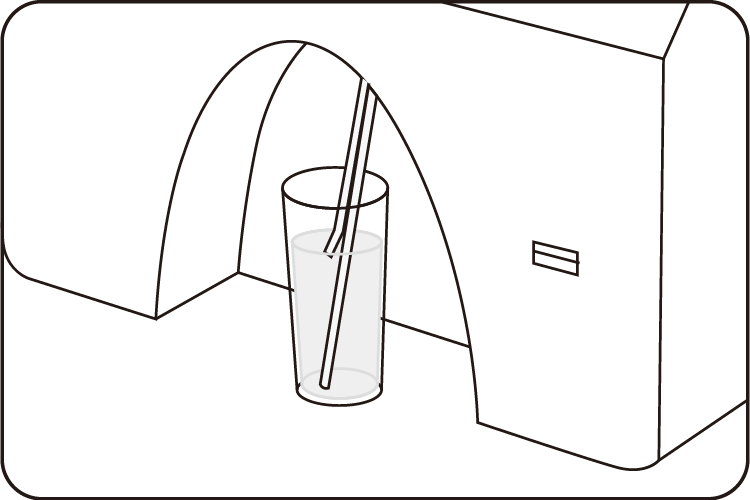

Start the self-cleaning program to remove the residue of previous sample

Place the milk sample below the detection port and insert the sensor

Select the detection parameters on the display interface and start testing

Interpret the result and assess the quality of the milk

After completing, restart the self-cleaning program to be ready for the next use

FAQ of Milk Tester

What equipment is used to test milk quality?

The commonly used equipment for testing milk quality is milk tester. It can quickly and non-destructively measure multiple indicators in milk and is suitable for daily quality monitoring in dairy farms, milk transportation and dairy processing factories.

What kind of maintenance does the milk tester need?

The commonly used equipment for testing milk quality is milk tester. It can quickly and non-destructively measure multiple indicators in milk and is suitable for daily quality monitoring in dairy farms, milk transportation and dairy processing factories.

Why is milk analysis important?

Milk analysis is of great significance. It not only ensures the quality and purity of the milk source, promptly detects adulterated or substandard milk sources, but also guides dairy farms and dairy enterprises to optimize production management, increasing milk output and quality.

Is a milk testing machine easy to use?

A milk testing machine is easy to operate. Just prepare the sample, place it in the detection port and start the device. Then, you can quickly obtain the test results. Even users without professional experimental backgrounds can quickly and accurately complete milk testing.

What is the correct way to take and prepare a milk sample?

First, thoroughly mix the milk to ensure that the sample is uniform. Then, take an appropriate amount of the sample and put it into a pollution-free container. Keep the sample at an appropriate temperature to avoid prolonged exposure or deterioration.

Can the milk tester be used for different types of milk?

The milk tester is suitable for various milk sources, including cow milk, goat milk, buffalo milk, donkey milk, camel milk and UHT milk. It can meet the testing needs of different dairy products in dairy farms, dairy processing factories and research institutions.

Can a milk analyzer be used in the transportation process?

Sure. Milk analyzer is not only suitable for use in dairy farms, but also can play an important role in the milk transportation process. The test can be conducted before transportation, during transportation or upon arrival at the terminal to ensure the quality and safety of the milk source.

What are the differences between ultrasonic milk analyzer and infrared milk analyzer?

Ultrasonic milk analyzer can conveniently test the milk through the principle of sound waves and is suitable for on-site use dairy farms. Infrared milk analyzer relies on infrared spectroscopy for precise analysis and is more suitable for laboratory or research environments.